Kopylets Mykhailo, Department of Information Systems and Networks

Lviv Polytechnic National University, Lviv, Ukraine

Abstract: The article is dedicated to the analysis of production, defining its key aspects, and developing an information system for effective monitoring and management of the enterprise. The proposed analytical system is based on the visualization of the production chain, allowing for real-time identification and resolution of issues during production. Business and user requirements, as well as functional and non-functional system requirements, are discussed. The system architecture is described, including the authorization service, API service, simulation core, and graphical interface.

Keywords: production analytics, information system, business requirements, user requirements, functional requirements, non-functional requirements

Production analytics is the process of collecting, analyzing, and interpreting data related to production activities [1]. It is done to gain valuable insights that can improve the efficiency of various parameters in the production process and overall predict potential problems before they become actual issues, allowing for swift responses to unforeseen events.

Production analytics can be viewed as working with physical production processes or as a general term for all processes contributing to the production of goods. In the latter sense, production analytics also encompasses areas such as inventory management, procurement, sales, and finance.

The purpose of developing an information system is to create a convenient tool for analyzing production processes in enterprises. Specifically, it involves building an analytical system that, based on the production scheme and certain parameters of the enterprise, calculates specific quantitative and qualitative characteristics. This enables more efficient and rapid decision-making regarding the modernization and optimization of the enterprise.

The primary function of the system is the visualization and identification of important characteristics for production processes at the enterprise through an information system in the form of a web application. Visualizing the production chain provides a broader view of the overall picture of the enterprise and its production processes. Visualization allows for a clear understanding of any issues in the production process, enabling analysis and the prompt implementation of effective solutions. The set of characteristics obtained from the calculations can be used in the analysis of the enterprise’s functioning and planning for its modernization.

Let’s define of requirements for our system. Requirements for any software are composed of three levels [2]: business requirements, user requirements, and functional requirements. In addition, each system also includes non-functional requirements.

The primary business requirements of the researched system include:

- Creation of a digital enterprise:

- Establishing a digital representation of the enterprise in the form of a production schema.

- Building a plan that provides entrepreneurs with the ability to visualize the comprehensive picture of the enterprise, including all its resources and production chains.

- Financial and production analysis capability:

- Providing entrepreneurs with the ability to conduct financial and production analyses.

- Enabling optimization of resources (financial, human resources, equipment, materials) in production and selecting an optimal strategy for enterprise improvement.

User requirements are the goals and tasks that the system addresses from the user’s perspective. Since the system has two types of users: the administrator and the entrepreneur (ordinary user), let’s describe the requirements for each of them.

The administrator has the ability to:

- Register and delete businesses and users.

- Set restrictions for users.

The user has the ability to:

- Modify personal data in the account.

- Configure resources (employees and equipment) used in the system.

- Build plans and diagrams for their business.

- View analytics and generate reports.

Functional requirements are the requirements for the functionality of the system that must be developed to achieve the goals of users and the business.

Functional requirements for the Administrator:

- Must have pre-defined login and password.

- Ability to log in and log out of the system.

- Registration of a new business.

- Registration of a new user.

- Adding a user to a business.

- Changing the business for a user.

- Setting restrictions for users.

- Deleting a user from the system.

Functional requirements for the User:

- Ability to log in and log out of the system.

- Changing the password.

- Viewing and editing their account information.

- Viewing restrictions set by the administrator.

- Adding, deleting, editing, and viewing employees.

- Adding, deleting, editing, and viewing equipment.

- Viewing the list of plans.

- Creating, editing, and deleting existing plans.

- Viewing analytics for a specific plan.

- Generating a report for a specific plan.

Non-functional requirements (quality attributes):

- Efficiency: The system should analyze user plans in a rational and efficient manner.

- Usability: The system should be convenient, understandable, and not require prior training for new users.

- Scalability: The system should work adequately for many users.

- Security: Users should have confidence that their personal data and plans will not be accessible to unauthorized individuals.

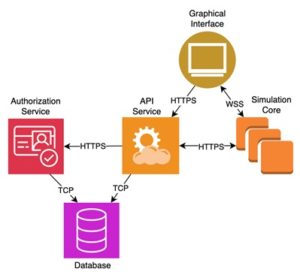

Figure 1. System architecture

Let’s also describe the architecture of a system (Figure 1) composed of the following software units:

Software Unit “Authorization Service”:

- Purpose – user and token management.

- Implementation language – C#, ASP.NET.

- Functionality – registration, user authorization, and authentication, issuance and verification of authorization tokens.

- Input data – login, password, email.

- Output data – authorization token.

- Invocation methods – HTTP/HTTPS requests.

Software Unit “API Service”:

- Purpose – management of system resources.

- Implementation language – C#, ASP.NET.

- Functionality – addition, editing, and deletion of resources such as employees, equipment, and plans.

- Input data – resource identifier and its state.

- Output data – resource or confirmation message.

- Invocation methods – HTTP/HTTPS requests.

Software Unit “Simulation Core”:

- Purpose – simulation of a complex plan.

- Implementation language – C#, ASP.NET.

- Functionality – step-by-step simulation calculation and report generation.

- Input data – search query.

- Output data – list of events corresponding to the query.

- Invocation methods – messages over WS/WSS connection.

Software Unit “Graphical Interface”:

- Purpose – graphical representation of components and interaction with users.

- Implementation language: HTML, CSS, JavaScript, React.js.

- Functionality – display of graphically represented components filled with information upon user request.

- Input data – user actions in the form of HTTP requests and WS messages.

- Output data – drawing corresponding graphical components.

- Invocation methods – user interaction in a web browser.

The conducted research and development of the production analytics information system revealed that this tool has significant potential for improving enterprise management. The use of the system not only allows for an efficient visualization of the production chain but also facilitates a comprehensive analysis of production parameters. The primary advantage of the system lies in its ability to promptly respond to potential issues, anticipate unknown events, and make quick decisions to optimize the enterprise. The implementation of business and user requirements in the system ensures its flexibility and suitability for various usage scenarios.

The specified non-functional requirements, such as efficiency, usability, scalability, and security, attest to the high quality of the system. The integration of different software units, including the authorization service, API service, simulation core, and graphical interface, forms a structured architecture that contributes to the convenient and effective use of the system.

Thus, the developed information system is a powerful tool for the analysis and optimization of production processes, contributing to the enhancement of the enterprise’s competitiveness in the market.

References

- Spotfire | Discover the Power of Manufacturing Analytics in Industry 4.0. Spotfire. URL: https://www.spotfire.com/glossary/what-is-manufacturing-analytics

- Software Requirements StudFiles. URL: https://studfile.net/preview/5130988/page:2/